Customer Reviews

Consumer Goods Manufacturer

Even PC beginners can easily check package information,

saving time for efforts towards business growth!

FANCL CORPORATION

Case of the Health Food Business Division

Interviewee

FANCL CORPORATION

Mr. Makoto Nagata of the Health Food Business Division

MIIDEL (hereafter referred to as M) : First off, could you share with us the background for implementing MIIDEL?

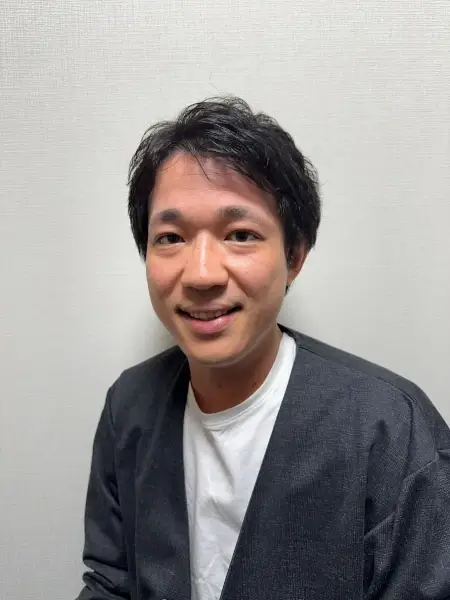

Mr. Nagata (honorifics omitted):I’m part of a department that oversees all processes involved in product development, from market analysis and acceptability studies to package design development. At the same time, there’s a strong demand for innovation and new initiatives. Hence, there was a desire to automate whatever tasks we could. For example, there’s the task of verifying printed materials like instructions and disclaimers that accompany health food products. Traditionally, this involves one person reading aloud and another visually checking to ensure all texts and marks are up-to-date. With regulations updating every 2-3 years, the workload increases, making it quite challenging. Considering the importance of accuracy to avoid product recalls, we looked into various software options to see if we could streamline this process while maintaining current precision levels.

M: What was the deciding factor in your adoption?

Nagata:Initially, we considered software from another vendor. However, we encountered issues like limited document format compatibility, which didn’t suit our operational environment. After conducting various searches online, we discovered MIIDEL. The introductory video was very clear, prompting us to apply for a trial. Once we started using it, we found it incredibly user-friendly for anyone. Believing that if even PC beginners could operate it and perform the same level of checks as experts, it would be beneficial across other departments, we proceeded with the trial.After confirming on-site that it could significantly save on work time and labor costs compared to traditional methods, we moved forward with its formal adoption. Currently, it is being utilized in departments we hadn’t initially considered, and we feel that the software has significantly contributed to streamlining our operations.

↑ Image documentation summarizing the automation of proofreading tasks and environmental improvements made possible by the introduction of MIIDEL (provided by Mr. Nagata)

M: It’s gratifying to hear that MIIDEL has been helpful in improving tasks that were previously burdened by excessive workloads.

Nagata:The package information verified by MIIDEL is critically important; any errors could lead to significant issues like product recalls. Manually checking this information is nerve-wracking and time-consuming, requiring multiple layers of verification to prevent incidents. I imagine others in this industry face similar stresses, and I would highly recommend it to them as well.

M: Thank you. With the realization of task automation, it becomes possible to reallocate manpower towards more innovative endeavors, doesn’t it?

Nagata:Exactly. We produce health products, but moving forward, it’s not just about selling these products; we also need to deliver services that encourage customers to continue using them in better ways. While we carry on with our current tasks, we’re also dedicating our spare time to new initiatives, all aimed at business growth.

M: It seems that the development of innovative products is indeed on the horizon. We greatly appreciate your time today in sharing such insightful perspectives!

This article is a translation of an interview conducted in Japanese.

Please refer to the Japanese page for accurate content.