Products / Service

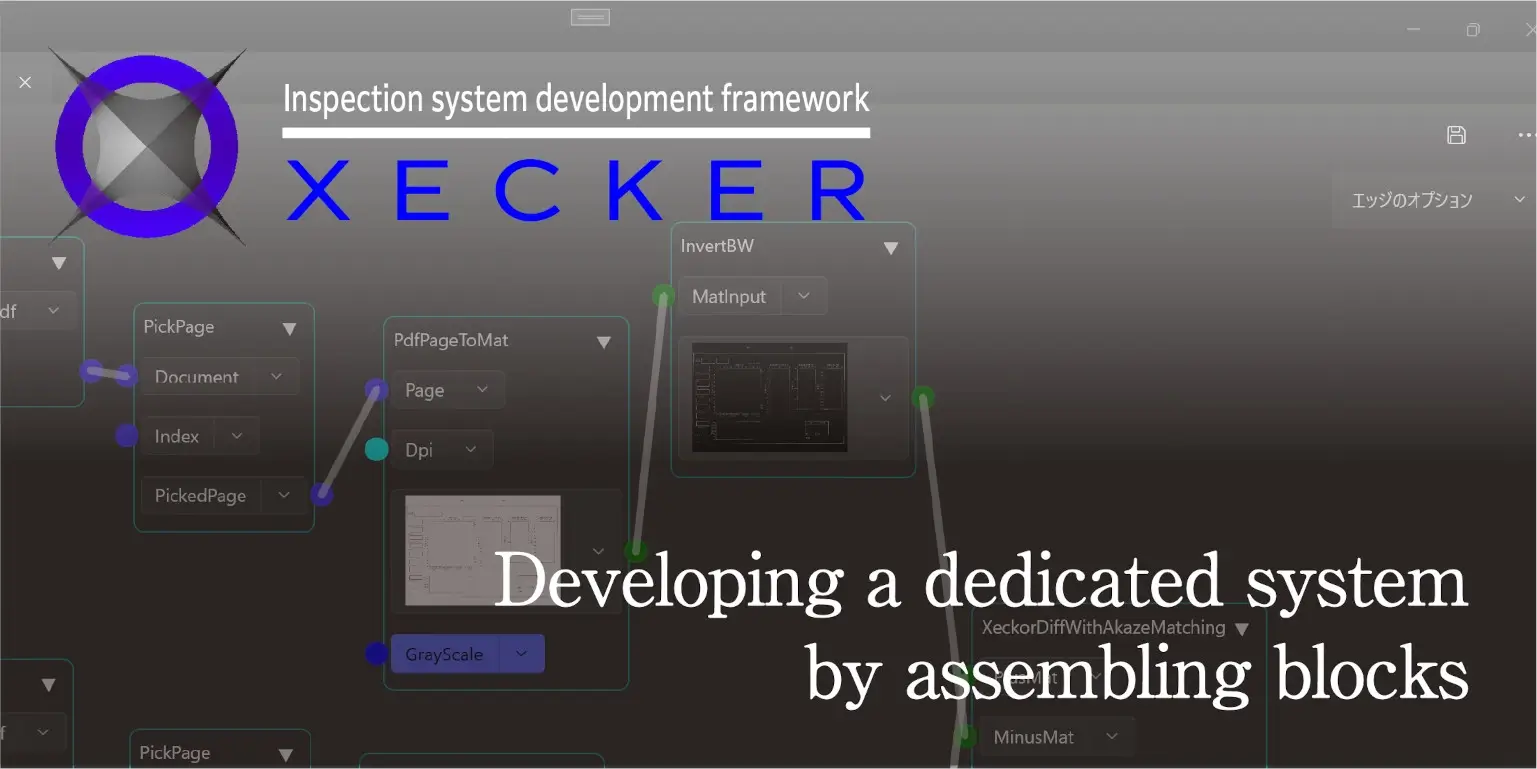

XECKER

A framework inspired by blocks

‘XECKER” is a framework for developing inspection systems required at various sites by assembling them like blocks according to their purposes. Compared to full-scratch development, we can provide a stable and dedicated system in a relatively short period of time.

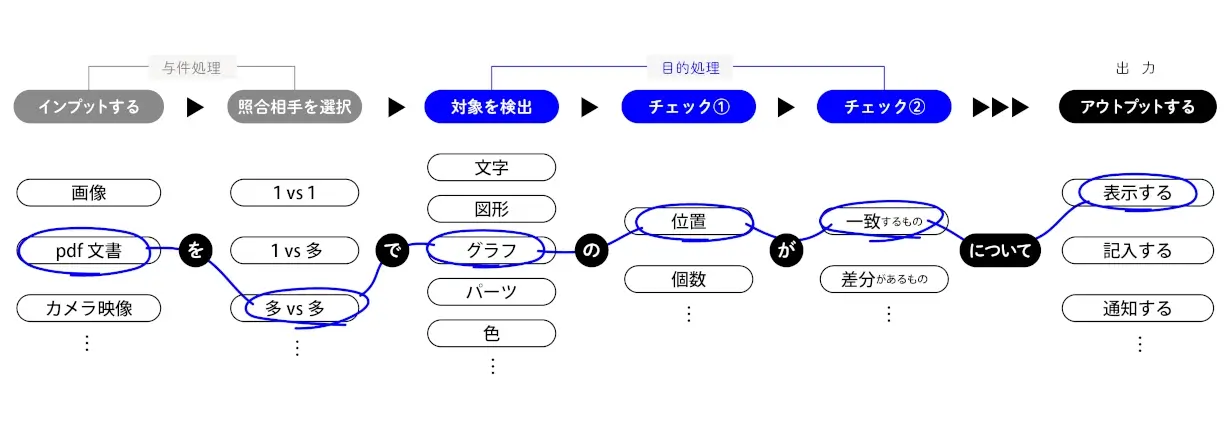

A wide variety of inspection systems are possible

While utilizing the modules provided as assets, we can also develop customize functions. Currently, in various scenarios of a wide range of industries, including inspection of drawings, product label checks, and inspecting measurement data, as well as utilizing TRIART’s unique ‘Composite AI 4CAS’ technology.

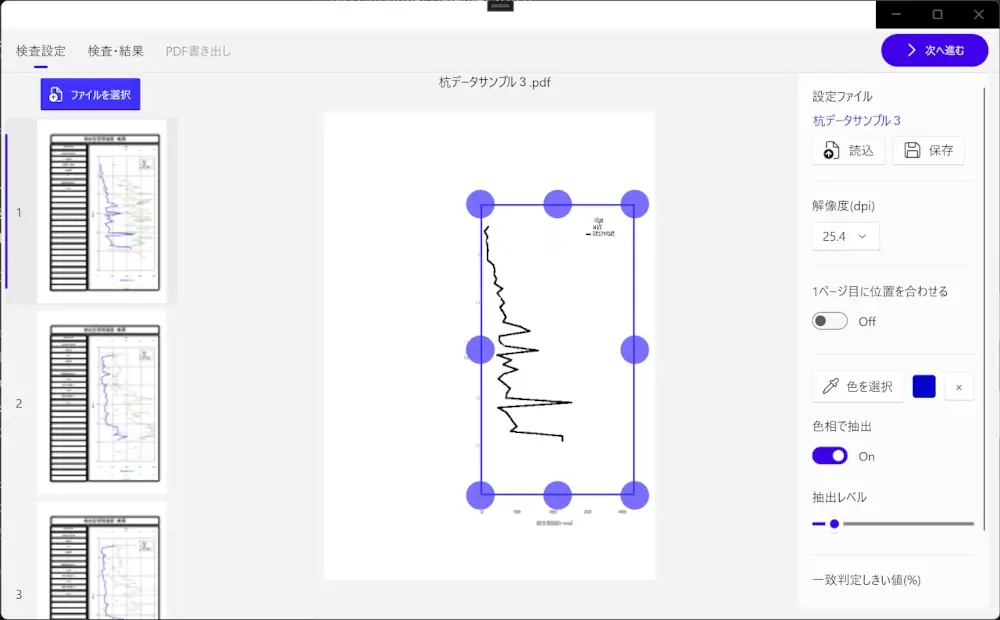

Development Case by XECKER

It has streamlined the resource-intensive and time-consuming task of checking a large number of graphs for a large number of combinations, allowing tasks that took a week to be performed accurately in about 10 minutes.

This system is utilized by major construction companies.

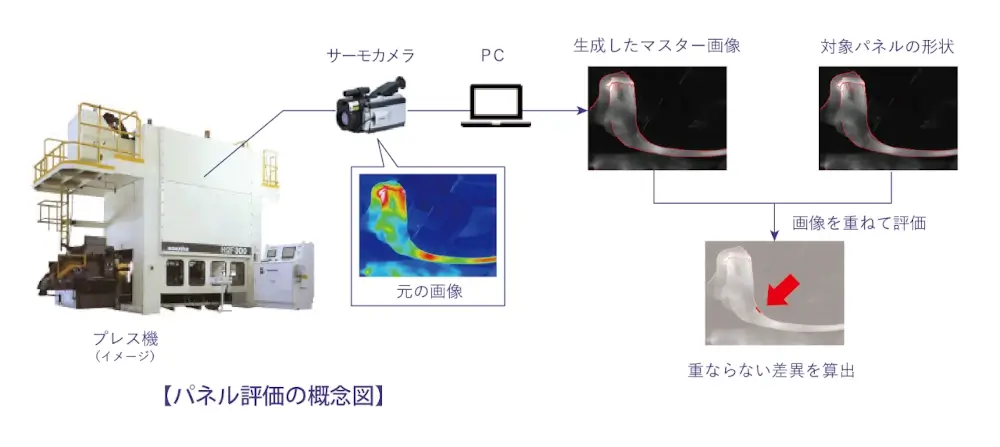

This system is designed to detect signs of defective parts from images of steel panels passing through press machines in an automobile factory, one after another.

TRIART’s unique image recognition AI judges thermal images from a thermo camera installed inside the press machine, and reproduces and passes on the skills of skilled workers while cooperating with the workers.

This achievement was realized through joint development with TOYOTA MORTOR KYUSHU,INC

※This photo is for illustrative purposes.

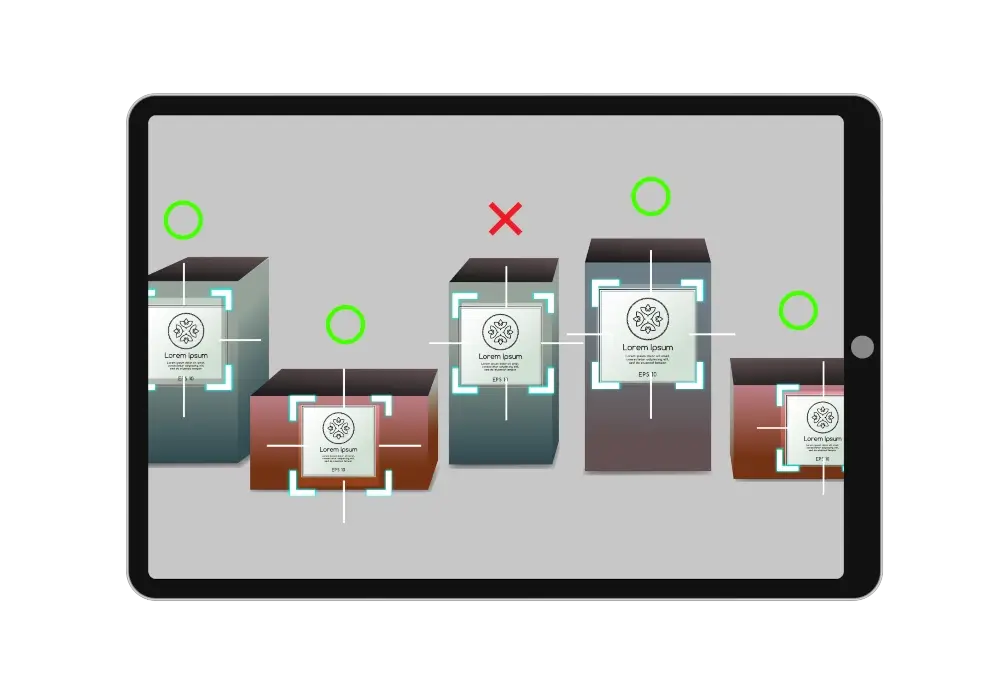

The system can determine the label design of the product and the indications with detailed product information over the camera image, so there is no need to convert the image into data, and the system can identify the individual product with a problem without error.

Furthermore, it can be operated with tablet PCs, Demonstrating mobility for product checks and inventories in warehouses and other onsite locations.

You can currently view the prototype.

First, request information