TRIART Co., Ltd. (Head Office: Iizuka City, Fukuoka Prefecture, Representative Director: Kentaro Imazu, hereinafter referred to as TRIART) and Toyota Motor Kyushu Corporation (Head Office: Miyawaka City, Fukuoka Prefecture, Representative Director and President: Osamu Nagata, hereinafter referred to as Toyota Kyushu), In Lexus production line at Toyota Kyushu Miyata Plant’s, we have begun testing a “Defective Premonition Sensing System”, which detect ultra-fine defects like that be discoverd sensually by skilled worker in advance through collaboration between humans and AI.

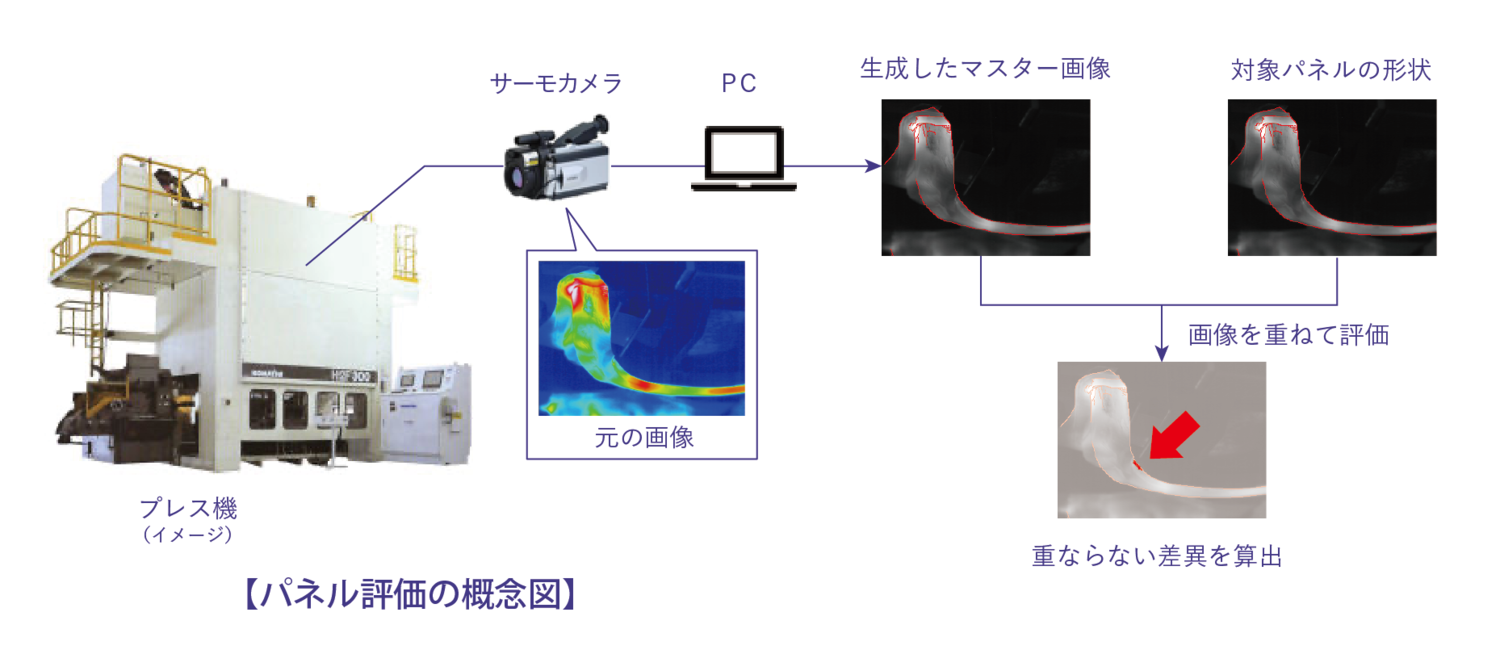

This technology uses images taken with a thermo camera installed inside the press machine to detect very slight deviations in the shape of mass-produced panels and differences in the degree of elongation of the steel plates during the “pressing process” in which panels are formed by applying pressure to the steel plates. This is what we detect. These differences can cause cracks or breakage after molding, and are important indicators that can lead to future product defects, but their detection has so far relied largely on the experience and intuition of skilled workers, and the generalization of skills It was a difficult field.

TRIART uses composite AI “4CAS” *1, an in-house technology with a proven track record in sensory information processing based on image data, to (1) generate a master image that serves as the standard shape of the panel from the thermo camera image and 2) calculate differences between the produced panel and the master image (expanded areas, contracted areas, etc.), we have made it possible to evaluate all the panels that are produced every 5 seconds. This makes it possible to decide the rules for “what kind of cases will causea defect to occur next ?” making it possible to more efficiently detect signs of defects with the accuracy of a skilled worker. What has dramatically improved the reliability and processing power of this evaluation is a unique work flow that the task of generating images in ① does not rely solely on AI learning, but rather allows workers to specify the rough shape midway through, returns to AI calculations again.

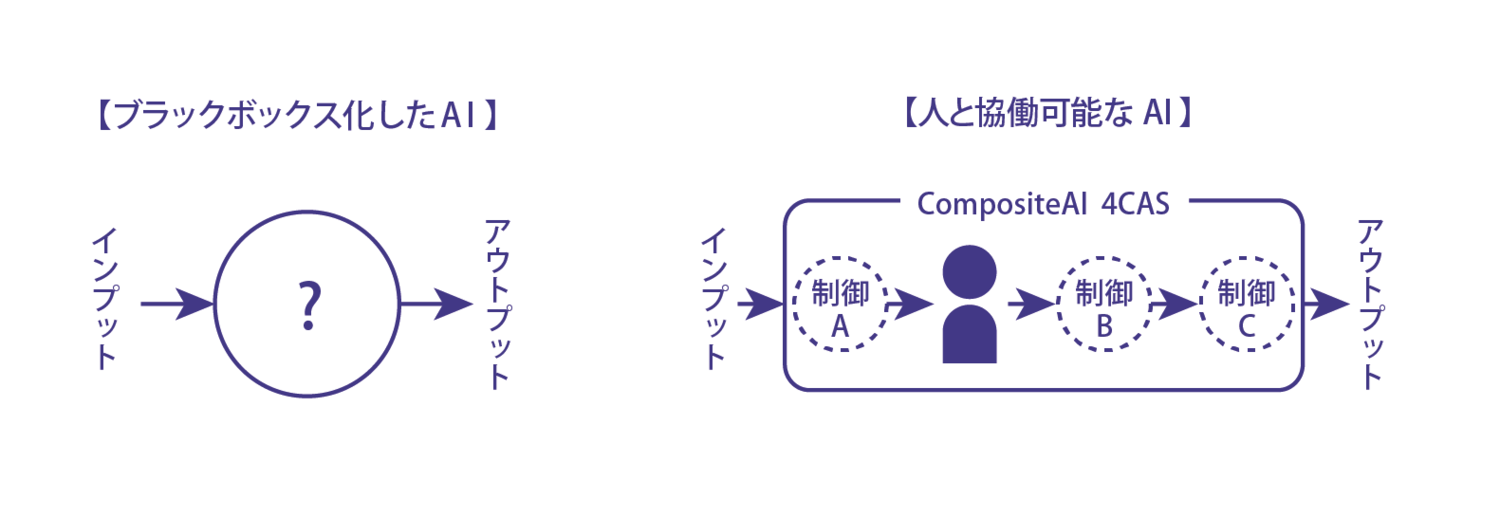

In DX (Digital Transformation) utilizing AI, there’s often an image of “full automation by AI,” but in tasks where the skills that workers have already acquired are utilized, or where human judgment is clearly superior, using power of human, designing a flow that complements each other with AI is thought to speed up the resolution of many issues. This is especially effective in manufacturing sites where there are a variety of parts and lines, and it is difficult to apply a system to all of them. This approach relies on the Composite AI “4CAS,” which does not make the AI process a black box and is composed of a series of control system AIs. The system jointly developed by Toyota Kyushu and TriArt can be considered a prime example of humans and AI working together on an equal footing in the physical setting of manufacturing.

The Toyota Kyushu Miyata Plant, as the world’s leading Lexus manufacturing base, has positioned skilled craftsmen at each process and has continued to maintain the top quality of its products*2. A factory is not only a place where products are manufactured but also a site where production technologies are developed. We hope that new production technologies like this will create additional capacity for skilled craftsmen to further refine their skills and sense, becoming a source for offering even more attractive products.

*1 Composite AI = Complex AI. There is a proven track record in processing sensibility information that is difficult to quantify, such as judgments made by human senses, and it has been implemented in the difference comparison function of the “Image Comparison System MIIDEL” currently being sold by TRIART.

*2 The Miyata Plant is widely known as one of the world’s leading automobile production sites, having won the highest Platinum award five times, tying for the world record in the plant category of the quality survey (Initial Quality Study, IQS) conducted by the American market research company J.D. Power.